A dealer’s in-depth guide to selecting the best door for the job

This article by Alpine Overhead Doors originally appeared in the Spring 2024 Edition of DASMA’s magazine, Door + Access Systems. Republished with permission.

> Click here to view the full edition of the magazine on DASMA’s site (PDF).

Editor’s note:

Alpine Overhead Doors has provided a one-of-a kind resource for dealers who regularly install rolling commercial doors and for those interested in pursuing the rolling door market. Do yourself a favor and read this story.

When it comes to commercial overhead doors, installers have a choice. While each door type comes with its own set of benefits and drawbacks, the ideal choice always comes down to the specific application, operating environment, and budget. Today, we’ll demystify the world of rolling doors. We’ll cover the main types, typical applications, and configuration options.

Let’s start with a basic definition: Rolling doors consist of curtains that roll up and coil around a pipe while opening. They are well known for being durable, secure, space-efficient, and customizable.

Their versatility allows them to be found in a wide range of commercial and specialty uses — from storefronts, warehouses, and counters to more demanding ones, such as military bases, high bay openings, and fire-rated and wind-loaded applications. Don’t let the name “doors” fool you, as they are often used to protect windows as well as entranceways.

Rolling doors are usually selected for applications where overhead space is limited and longevity and low maintenance are desired. Most installers find them relatively easy to install and generally easy to service. If you haven’t sold or installed a rolling door, then you’ve likely seen or perhaps serviced one.

Their exceptional functionality is balanced by simple but rugged aesthetics — their appearance can be enhanced by material and finish options, such as polished steel, powder coating, and anodizing. Slats may also be accented by fenestration, which allows airflow, or window-like punch-outs that add light and visibility.

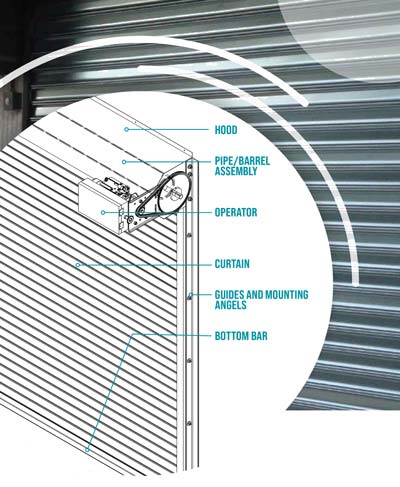

The anatomy of a rolling door

The primary components of an overhead rolling door include a curtain, bottom bar, pipeshaft, bracket plates, guides with mounting angles, hood, and operator. The curtain is fabricated using interlocking roll- formed slats on service doors or metal rods connected by links to form a grille pattern.

The primary components of an overhead rolling door include a curtain, bottom bar, pipeshaft, bracket plates, guides with mounting angles, hood, and operator. The curtain is fabricated using interlocking roll- formed slats on service doors or metal rods connected by links to form a grille pattern.

Slats may be flat or curved and are available in multiple gauges and alloys of steel, aluminum, and other materials. The slats are fastened together using end locks or wind locks, which prevent the individual slats from separating laterally and provide an additional level of security.

At the top of the assembly, the curtain attaches to a horizontal operator- or manually-driven spring-loaded pipe, which is secured to bracket plates at both ends. These plates attach to mounting angles that span the entire height of the door on both the left and right sides of the opening. During operation, the curtain travels upwards within vertical guides, which are fastened to the mounting angles, and rolls around the pipeshaft. Newer high-speed high-cycle door models feature springless operation by utilizing direct drive operators.

When closing, the curtain travels downwards, uncoiling from the pipe, and seals the opening. A bottom bar, located at the bottom of the curtain, adds rigidity and prevents overtravel of the curtain in either direction. Optionally, the bottom bar may include a locking mechanism, a rubber seal for draft reduction, or a sensing edge for safety. A non-load-bearing hood at the top conceals and protects both the pipe and the curtain.

Rolling door operation options include manual push-up, hand chain, hand crank or electric operator. Many choices are offered for material, insulation, finish, control, security, and safety.

Types and applications

Rolling doors are not a “one-size-fits-all” solution. Design and construction features can be highly customized to suit an incredibly diverse range of uses and mounting conditions. Categorization and options for rolling steel doors vary among manufacturers. The types mentioned in this article cover most of what’s available on the

market today.

If you’re not sure which door is ideal for a particular job, no worries. Just explain to a rolling door sales representative where and how the door will be used, the dimensions, and the environment in which it will be operating. They will be happy to tell you which door(s) and options are best suited for your specific needs. We want you to be prepared and confident when specifying rolling doors, so let’s review the main styles available:

Service doors represent the largest category of rolling doors in terms of popularity and use. Their curtains are usually flat or curved slats that are configured for specific uses. Rolling service doors are found in many applications such as warehouses, loading docks, parking garages, aircraft hangars, fire houses, truck terminals, and countless others. Insulated doors, which help reduce energy costs, can be filled with polystyrene, polyurethane, or other insulating materials. They feature better thermal performance and rigidity.

Service doors represent the largest category of rolling doors in terms of popularity and use. Their curtains are usually flat or curved slats that are configured for specific uses. Rolling service doors are found in many applications such as warehouses, loading docks, parking garages, aircraft hangars, fire houses, truck terminals, and countless others. Insulated doors, which help reduce energy costs, can be filled with polystyrene, polyurethane, or other insulating materials. They feature better thermal performance and rigidity.

Sound-rated service doors feature a higher Sound Transmission Class (STC) rating and are specifically designed to dampen sound. These doors are found in music studios, theaters, concert venues, noisy warehouses, and other locations in which sound dampening is needed. Doors with perforated slats (consisting of hundreds of small punched holes) are also offered for uses where ventilation and visibility are required.

Grilles are ideal for any application that requires security with greater visibility and ventilation. The curtain consists of horizontal rods, usually made from galvanized steel for strength and rust resistance, that run continuously across the opening. The rods are connected by vertical links and are typically made from aluminum for lighter weight or stainless steel for rigidity and corrosion resistance. These links may or may not be continuous. If they aren’t continuous, then the rods are covered with tube spacers (also known as sleeves) to maintain the space between the links. These spacers are typically made from aluminum, stainless steel, or PVC.

Grilles are ideal for any application that requires security with greater visibility and ventilation. The curtain consists of horizontal rods, usually made from galvanized steel for strength and rust resistance, that run continuously across the opening. The rods are connected by vertical links and are typically made from aluminum for lighter weight or stainless steel for rigidity and corrosion resistance. These links may or may not be continuous. If they aren’t continuous, then the rods are covered with tube spacers (also known as sleeves) to maintain the space between the links. These spacers are typically made from aluminum, stainless steel, or PVC.

Manufacturers may offer PVC or anodized steel in various colors to enhance the grille’s appearance. The rods and links may be configured as a straight pattern or, optionally, as a brick pattern if the vertical links are not continuous. Rolling grilles are used in applications such as service windows, malls, interior/exterior storefronts, pharmacies, parking garages, hospitals, municipal facilities, and many other uses.

Storefront doors refers more to an application than a particular door type. While both service doors and grilles can be used for storefronts, there are product options designed for lower-cycle use. A typical storefront door or window shutter goes up in the morning and comes down at night, whereas a service door in a warehouse or

Storefront doors refers more to an application than a particular door type. While both service doors and grilles can be used for storefronts, there are product options designed for lower-cycle use. A typical storefront door or window shutter goes up in the morning and comes down at night, whereas a service door in a warehouse or

parking garage may be cycled many times each day.

For lower-cycle applications, a band (or clock) spring pipe may be used instead of a torsion spring pipe coupled with a basic operator. These models are typically found in densely populated cities and are less expensive than a typical service door, which helps to reduce the upfront cost of the door. However, there is a tradeoff: lower longevity, with ratings as low as ~7,500 cycles.

A service door will typically offer up to 20,000 cycles and can be designed for 300,000 or more cycles depending on the operator, spring selection, and other design factors. Storefront doors are seen covering entranceways and windows in front of free-standing retail establishments, strip malls, commercial districts, storage units, and light-duty industrial settings.

Counter doors/shutters are used for smaller openings and come with either a solid slat or grille curtain. Since they are typically much smaller than entranceway doors, they have less demanding operational requirements and have scaled-down features, including the size of the slat profile, guides, and hood box.

Counter doors/shutters are used for smaller openings and come with either a solid slat or grille curtain. Since they are typically much smaller than entranceway doors, they have less demanding operational requirements and have scaled-down features, including the size of the slat profile, guides, and hood box.

Some manufacturers offer counter shutters with an integrated preassembled frame and countertop sill, which creates a clean, finished appearance without exposed edges. For more traditionally styled spaces, wooden shutters, built in a variety of wood types, are also available.

Counter doors with fire and/or smoke ratings are also available. Shutters are found in concession stands, school cafeterias, healthcare facilities, pharmacies, mall kiosks, parts counters, box offices, bank counters, and many other applications.

Fire-rated/Smoke-rated doors, as the name implies, are designed to contain the spread of fire and smoke. They work by closing automatically when activated in the event of a fire and are durable enough to withstand intense heat for a specified period. Smoke-rated doors have perimeter seals to keep smoke from passing through.

Fire-rated/Smoke-rated doors, as the name implies, are designed to contain the spread of fire and smoke. They work by closing automatically when activated in the event of a fire and are durable enough to withstand intense heat for a specified period. Smoke-rated doors have perimeter seals to keep smoke from passing through.

Fire/Smoke-rated doors are activated by either a fusible link or an auto-resettable operator. Fusible links are activated by an increase in temperature. They melt when the temperature reaches a fixed level, typically 165 F, thus releasing the tension that holds the door and allowing the door to close. Afterward, a new link needs to be installed and the tension may need to be reset, which creates a service opportunity for installers.

In an auto-reset setup, an event, such as power failure, fire/smoke alarm signal, break of a fusible link, or test activation triggers the door to drop. When triggered, both the centrifugal governor and constant-hold brakes release. They do not lose tension after testing/ activation and do not need to be mechanically reset. Auto resettable doors require an operator designed for this purpose.

Fire-rated doors are regulated by a variety of local, national, and global agencies. Certifications of fire door design and manufacturing to stated performance specifications are managed by multiple entities, such as UL and other testing/approval agencies. Ultimately, the Authorities Having Jurisdiction (AHJ) maintain and enforce codes for fire door requirements and testing for a given location.

Annual inspections and testing are mandated by The National Fire Protection Association (NFPA) to ensure that the door is properly functioning. The test must be done by a qualified individual (typically door technicians). They are required to do a visual inspection, confirm all methods of operation, and perform a drop test and reset. As a result, fire doors can offer good recurring revenue opportunities for door installation professionals.

Rolling fire doors are found in any building or facility that requires a fire door and anywhere where fire protection is a concern or mandated by the AHJ.

Storm-rated rolling doors are engineered to withstand threats, such as wind, from storms, hurricanes, tornadoes, or forced entry. Like fire doors, storm-rated doors have their own set of certifications, which include the Miami-Dade approval for high velocity and Florida Department of Community Affairs approvals.

Storm-rated rolling doors are engineered to withstand threats, such as wind, from storms, hurricanes, tornadoes, or forced entry. Like fire doors, storm-rated doors have their own set of certifications, which include the Miami-Dade approval for high velocity and Florida Department of Community Affairs approvals.

FEMA provides an even stricter standard, known as ICC 500-2014/ FEMA P-361-2015, for doors that protect against extremely high winds and flying debris. These doors are approved for safe rooms in schools or other public buildings used for evacuations during an extreme weather event.

Storm-rated doors are generally made with thicker gauge steel, reinforced guides, and heavy-duty wind locks to secure the curtain in place when subjected to high winds and debris. The door can be insulated if required. They can also be activated by an alarm or panic button.

Specialty rolling doors is a category that encompasses anything other than what’s been already covered. These include springless, highspeed, and high-cycle doors, as well as rolling doors with an integrated pass door or wicket.

Specialty rolling doors is a category that encompasses anything other than what’s been already covered. These include springless, highspeed, and high-cycle doors, as well as rolling doors with an integrated pass door or wicket.

For marine and other extreme environment applications, curtains are made with heavier-gauge, corrosion-resistant materials as well as other structural reinforcements and design considerations. The specialty category also contains combination rolling doors. These are comprised of two separate curtains, typically a standard slat door and a grille door, which operate independently but cover the same opening. A grille by day for visibility, security, and airflow; solid slats by night for better security and environmental control.

Let’s roll!

As you can see, rolling doors are extremely diverse in their design, use, and functionality. In addition to the many types we covered, there’s an extensive variety of options for operation, finish, safety, and security — but we’ll save those for another day.

If you’d like to learn more about rolling steel doors, their applications, and installation information, reach out to a rolling door manufacturer. Most of them offer educational support programs to help you better understand how to sell, install, test, and maintain these durable and versatile commercial doors.

The article was written by Philip Paranicas with the help of Sean Morelli and Matthew Padelli of Alpine Overhead Doors. Alpine is a leading manufacturer of quality overhead rolling door systems since 1972. Offerings include service doors, insulated doors, fire and storm rated doors, storefront doors, shutters, grilles, and high performance coiling doors.

All of their products are proudly made in the U.S. To learn more about Alpine’s doors, specifications, and applications, visit https://www.alpinedoors.com.